Mining

2008/9 Schools Wikipedia Selection. Related subjects: Business

Mining is the extraction of valuable minerals or other geological materials from the earth, usually (but not always) from an ore body, vein or (coal) seam. Materials recovered by mining include bauxite, coal, copper, gold, silver, diamonds, iron, precious metals, lead, limestone, magnesite, nickel, phosphate, oil shale, rock salt, tin, uranium and molybdenum. Any material that cannot be grown from agricultural processes, or created artificially in a laboratory or factory, is usually mined. Mining in a wider sense comprises extraction of any non-renewable resource (e.g., petroleum, natural gas, or even water).

History

Since the beginning of civilization people have used stone, ceramics and, later, metals found on or close to the Earth's surface. These were used to manufacture early tools and weapons. For example, high quality flint found in northern France and southern England were used to set fire and break rock. Flint mines have been found in chalk areas where seams of the stone were followed underground by shafts and galleries. The mines at Grimes Graves are especially famous, and like most other flint mines, are Neolithic in origin (ca 4000 BC-ca 3000 BC). Other hard rocks mined or collected for axes included the greenstone of the Langdale axe industry based in the English Lake District.

The oldest known mine on archaeological record is the "Lion Cave" in Swaziland. At this site, which by radiocarbon dating the mine dates around 4,100 BC, paleolithic humans mined mineral hematite, which contained iron and was ground to produce the red pigment ochre. Mines of a similar age in Hungary and are believed to be sites where Neanderthals may have mined flint for weapons and tools.

Ancient Egyptians mined malachite at Maadi. At first, Egyptians used the bright green malachite stones for ornamentations and pottery. Later, between 2,613 and 2,494 BC, large building projects required expeditions abroad to the area of Wadi Maghara in order "to secure minerals and other resources not available in Egypt itself." Quarries for turqoise and copper were also found at "Wadi Hamamat, Tura, Aswan and various other Nubian sites" on the Sinai Peninsula and at Timna. Mining in Egypt occurred in the earliest dynasties, and the gold mines of Nubia were among the largest and most extensive of any in Ancient Egypt, and are described by the Greek author Diodorus Siculus. He mentions that fire-setting was one method used to break down the hard rock holding the gold. One of the complexes is shown in one of earliest known maps. They crushed the ore and ground it to a fine powder before washing the powder for the gold dust.

Europe

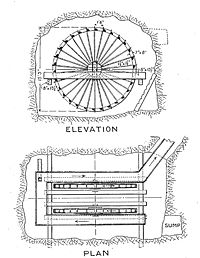

Mining in Europe has a very long pedigree, examples including the silver mines of Laurium, which helped the establishment of the Greek city state, especially Athens. However, it is the Romans who developed large scale mining methods, especially the use of large volumes of water brought to the minehead by numerous aqueducts. The water was used for a variety of purposes, and included using it to remove overburden and rock debris, as well as washing comminuted or crushed ores, and driving simple machinery. Spain was one of the most important mining regions, but all regions of the Roman Empire were exploited. They used reverse overshot water-wheels for dewatering their deep mines such as those at Rio Tinto. The Celts, for example, who were native to Britain, had mined minerals for centuries, but when the Romans came, the scale of the operations changed dramatically. The Romans needed what Britain possessed, especially gold, silver, tin and lead. Mining in the Medieval period is best known through the work De Re Metallica (1556) of Georg Agricola, who described many different mining methods then used in German or Saxon mines. Use of water power in the form of water mills was extensive, and were employed in crushing ore, raising ore from shafts and ventilating galleries by giant bellows.

Black powder was first used in mining in Banská Štiavnica, Kingdom of Hungary present-day Slovakia in 1627. In 1762, the world's first mining academy was established in the same town.

Britain

Britain's gold mines were located in Wales at Dolgellau and Dolaucothi. Romans discovered the Dolaucothi vein after the invasion, in about 74 AD, and a settlement was soon set up in the Cothi Valley protected by a fort. They used hydraulic mining methods on a large scale to prospect for the veins of ore, especially a now redundant form of mining known as hushing. It involved building numerous aqueducts to supply water to the minehead where it was stored in large reservoirs and tanks. When a full tank was opened, the wave of water sluiced away the overburden to expose the bedrock underneath and any gold veins. The rock was attacked by fire-setting to heat the rock, which would then be quenched with a stream of water. The thermal shock cracked the rock, enabling it to be removed, aided by further streams of water from the overhead tanks. They used similar methods to work cassiterite deposits in Cornwall and lead ore in the Pennines. The methods had been developed by the Romans in Spain in 25 AD to exploit large alluvial gold deposits, the largest site being at Las Medulas, where seven long aqueducts were built to tap local rivers and to sluice the deposits.

They followed the ore veins underground once opencast mining was no longer feasible. At Dolaucothi they stoped out the veins, and drove adits through barren rock to drain the stopes. Alternatively, the veins may have been trenched, keeping the upper part open to the air. At deeper levels, stoping will have been necessary. The same adits were also used to ventilate the workings, especially important when fire-setting was used. At other parts of the site, they penetrated the water table and dewatered the mines using several kinds of machine, especially reverse overshot water-wheels. They were used extensively in the copper mines at Rio Tinto in Spain, where one sequence comprised 16 such wheels arranged in pairs, and lifting water about 80 feet (24 m). They were worked as treadmills with miners standing on the top slats. Many examples of such devices have been found in old Roman mines and some examples are now preserved in the British Museum and the National Museum of Wales.

Lead and silver were widely exploited during the Roman period, in Wales, the Mendips and Pennines. A lead-silver mine at Charterhouse, Somerset for example, was guarded by a small fort and was next to the mine workings and settlement for the miners. Lead pigs have been found at several localities in Britain, and mining was so successful, that the Spanish complained about over-production depressing the market. The silver was valuable bullion, while the lead found numerous applications, especially in roofing and plumbing.

There were many iron mines in Roman Britain. The index to the Ordnance Survey Map of Roman Britain lists 33 iron mines: 67% of these are in the Weald and 15% in the Forest of Dean. The majority of mine workers were slaves. The work conditions were poor, and up to 12% of miners died every year.

North America

In North America there are ancient, prehistoric copper mines along Lake Superior. "Indians availed themselves of this copper starting at least 5000 years ago," and copper tools, arrowheads, and other artifacts that were part of an extensive native trade network have been discovered. In addition, obsidian, flint, and other minerals were mined, worked, and traded. While the early French explorers that encountered the sites made no use of the metals due to the difficulties in transporting it, the copper was eventually traded throughout the continent along major river routes. In Manitoba, Canada, there also are ancient quartz mines near Waddy Lake and surrounding regions.

In the early colonial history of the Americas, "native gold and silver was quickly expropriated and sent back to Spain in fleets of gold- and silver-laden galleons." Turquoise dated at 700 A.D. was mined in pre-Columbian America; in the Cerillos Mining District in New Mexico, estimates are that "about 15,000 tons of rock had been removed from Mt Chalchihuitl using stone tools before 1700."

Mining in the United States became prevalent in the 19th century. As with the California Gold Rush in the mid 1800s, mining for minerals and precious metals alongside ranching was very important in the Westward Expansion to the Pacific coast. With the exploration of the West, mining camps were established and "expressed a distinctive spirit, an enduring legacy to the new nation;" Gold Rushers would experience the same problems as the Land Rushers of the transient West that preceded them. Aided by railroads, many traveled West for work opportunities in mining. Western cities such as Denver and Sacramento originated as mining towns.

Procedure

Steps of process

- Prospecting or Exploration to find and then define the extent and value of ore where it is located ("ore body")

- Conduct resource estimation to mathematically estimate the size and grade of the deposit

- Conduct a pre-feasibility study to determine the theoretical economics of the ore deposit. This identifies, early on, whether further investment in estimation and engineering studies is warranted and identifies key risks and areas for further work.

- Conduct a feasibility study to evaluate the financial viability, technical and financial risks and robustness of the project and make a decision as whether to develop or walk away from a proposed mine project. This includes mine planning to evaluate the economically recoverable portion of the deposit, the metallurgy and ore recoverability, marketability and payability of the ore concentrates, engineering, milling and infrastructure costs, finance and equity requirements and a cradle to grave analysis of the possible mine, from the initial excavation all the way through to reclamation.

- Development to create access to an ore body and building of mine plant and equipment

- The operation of the mine in an active sense

- Reclamation to make land where a mine had been suitable for future use

Techniques

Mining techniques can be divided into two basic excavation types:

|

|

In-situ leach is a particular mining technique that is used to mine minerals ( potash, potassium chloride, sodium chloride, sodium sulfate and uranium oxide) which dissolve in water.

Extractive metallurgy

The science of extractive metallurgy is a specialized area in the science of metallurgy that studies the extraction of valuable metals and minerals from their ores, especially through chemical or mechanical means. Mineral processing (or mineral dressing) is a specialized area in the science of metallurgy that studies the mechanical means of crushing, grinding, and washing that enable the separation (extractive metallurgy) of valuable metals or minerals from their gangue (waste material).

Environmental effects

Environmental issues can include erosion, formation of sinkholes, loss of biodiversity, and contamination of groundwaters and surface water by chemicals from the mining process and products.

Modern mining companies in some countries are required to follow environmental and rehabilitation codes, ensuring the area mined is returned to close to its original state. In some countries with pristine environments, such as large parts of Australia, this is impossible despite the best intentions. Some mining methods have devastating environmental and public health effects.

Mining can have adverse effects on surrounding surface and ground water if protection measures are not exercised. The result can be unnaturally high concentrations of some chemical elements, notably arsenic and sulfuric acid, over a significantly large area of surface or subsurface. Coal mining releases approximately twenty toxic chemicals, of which 85% is said to be managed on site. Combined with the effects of water and the new 'channels' created for water to travel through, collect in, and contact with these chemicals, a situation is created in which massive contamination can occur. In well-regulated mines, hydrologists and geologists take careful measures to mitigate any type of water contamination that could be caused by mines. In modern American mining, operations must, under federal and state law, meet standards for protecting surface and ground waters from contamination, including acid mine drainage (AMD). To mitigate these problems water is continuously monitored at coal mines. The five principal technologies used to control water flow at mine sites are: diversion systems, containment ponds, groundwater pumping systems, subsurface drainage systems, and subsurface barriers. In the case of AMD, contaminated water is generally pumped to a treatment facility that neutralizes the contaminants.

Some examples of environmental problems associated with mining operations are:

- Ashio Copper Mine, Ashio, Japan was the site of substantial pollution at end of the nineteenth century

- Acid mine drainage, exemplified by the cases of the Berkeley Lake Mine, and the Wheal Jane Mine

- Dissolution and transport of dissolved metals and heavy metals by run-off and ground waters, an example being the Britannia Mine, a former copper mine near Vancouver, British Columbia. Tar Creek, an abandoned mining area in Picher, Oklahoma that is now an Environmental Protection Agency superfund site. Water in the mine has leaked through into local groundwater, contaminating it with metals such as lead and cadmium.

- Long-term storage of tailings and dust, which can be easily blown off site by wind, an example being Scouriotissa, an abandoned copper mine in Cyprus.

- Erosion of exposed hillsides, mine dumps, tailings dams and resultant siltation of drainages, creeks and rivers, the prime example being the giant Ok Tedi Mine in Papua New Guinea.

- In areas of wilderness mining may cause habitat destruction and destruction or disturbance of ecosystems, and in areas of farming it may disturb or destroy productive grazing and cropping lands. In urbanised environments mining may produce noise pollution, dust pollution and visual pollution.

Although such issues have been associated with some mining operations in the past, modern mining practices have improved significantly and are subject to close environmental scrutiny. Modern mining practises aim to lessen environmental impacts from mining, and the ultimate aim is to return the local environment to as close to pristine as is possible. In many cases, the most significant environmental impact longer-term is visual, with pits and mine dumps prominent landscape features.

To ensure completion of reclamation (restoring mine land) most governments and regulatory authorities around the world require that mining companies post a bond to be held in escrow until productivity of reclaimed land has been convincingly demonstrated. Since 1978 the mining industry has reclaimed more than 2 million acres (8,000 km²) of land in the United States alone. This reclaimed land has renewed vegetation and wildlife in previous mining lands and can even be used for farming and ranching.

For further reading on reclamation of former mining sites, please see Restoration ecology.

Mining industry

Overview

While exploration and mining can sometimes be conducted by individual entrepreneurs or small business, most modern-day mines are large enterprises requiring large amounts of capital to establish. Consequently, the mining sector of the industry is dominated by large, often multinational, mostly publicly-listed companies. See Category:Mining companies for a list. However, what is referred to as the 'mining industry' is actually two sectors, one specializing in exploration for new resources, the other specializing in mining those resources. The exploration sector is typically made up of individuals and small mineral resource companies dependent on public investment. The mining sector is typically large and multi-national companies sustained by mineral production from their mining operations.

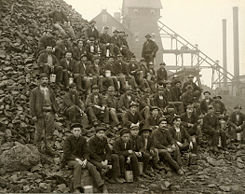

Employment

United States

Miners today do more than just dig in the Earth's subsurface. There are many different jobs, direct and indirect, in the mining industry, ranging from engineers and lab technicians to geologists and environmental specialists. Beyond employment directly linked to mine-site activity, the modern mining industry also employs many other professionals, including accountants, lawyers, sales representatives, public relations specialists, not to mention thousands of men and women involved who manufacture the machines and equipment necessary to mine minerals.

Employment in the mining industry offers highly competitive wages and benefits, especially in rural or remote areas. According to the Bureau of Labor Statistics (BLS), wages for coal miners are 30% higher than the wage earned by the average American. Employees possessing at least a bachelor's degree in mining or geological engineering can earn a median pay of over $80,000 annually.

The US Bureau of Labor Statistics estimates that 675,000 are employed in the natural resources and mining sector. Estimated employment by selected specific commodity (including mine, mill, smelter, and quarry workers) listed below is from US Geological Survey Mineral Commodity Surveys:

- Crushed Stone - 79,700 workers

- Copper - 7,000

- Cement - 18,000

- Sand and Gravel - 38,300

- Gold - 7,600

- Aluminium - 56,000

- Iron Ore - 4,400

- Platinum Group Metals - 1,600

- Salt - 4,100

- Phosphate Rock - 2,900

The mining industry has an experienced but aging workforce with a mean average age of 50 years and median of 46 years. Indeed, while the industry will require new employees to meet future demand, the largest dilemma currently facing mine operators is finding employees to fill vacancies left by a generation of miners, mine engineers, senior managers, technical experts and others who are set to retire between 2005 and 2015. However, the industry is struggling to meet that demand due to current low enrollment levels in mining education programs at American colleges and universities.

Mining is regulated under a comprehensive federal safety law (Federal Mine Safety and Health Act) that is administered by the Department of Labor's Mine Safety and Health Administration (MSHA). Currently under federal law, and enforced by MSHA each U.S. miner must have an approved worker training program in health and safety issues, including at least 40 hours of basic safety training for new underground miners with no experience; 24 hours for new miners at surface mines with no experience; plus eight hours of annual refresher training for all miners.

Safety

United States

Safety has long been a controversial issue in the mining business especially with sub-surface mining. While mining today is substantially safer than it was in the previous decades, mining accidents are often very high profile, such as the Quecreek Mine Rescue saving 9 trapped Pennsylvania coal miners in 2002.

Mining ventilation is often seen to be a safety concern for many miners and their families. Poor ventilation of the mines causes exposure to harmful gases, heat and dust inside sub-surface mines. These can cause harmful physiological effects, even death. The concentration of methane and other airborne contaminants underground can generally be controlled by dilution (ventilation), capture before entering the host air stream (methane drainage), or isolation (seals and stoppings).

Methane gas is a common source of ignition for explosions in coal mines and can propagate into the more violent coal dust explosions. Explosions can be prevented or mitigated by eliminating ignition sources, minimizing methane concentrations and coal dust accumulations, generalized rock dusting, and by using passive and active barriers to suppress propagating explosions. High temperatures and humidity may result in heat-related illnesses, including heat stroke which can be fatal. Dusts can cause lung problems, including silicosis, asbestosis and pneumoconiosis (also known as miners lung or black lung disease).

A ventilation system is set up to course a stream of air through the working areas of the mine. The air circulation necessary for the effective ventilation of a mine is generated by one or more large mine fans, usually located above ground. In the United States, the main fans at coal mines are required to be above ground. Air flows in one direction only, making circuits through the mine such that each main work area receives a supply of fresh air.

Mining is regulated under the federal Mine Safety and Health Act by MSHA, which employs nearly one safety inspector for every four coal mines. Underground coal mines are thoroughly inspected at least four times annually by MSHA inspectors. In addition, miners can report violations, and request additional inspections. Miners with such concerns for their work safety cannot be penalized with any threat to the loss of employment.

Immediately reportable accidents and injuries are:

- A death of an individual at a mine;

- An injury to an individual at a mine which has a reasonable potential to cause death;

- An entrapment of an individual for more than thirty minutes;

- An unplanned inundation of a mine by a liquid or gas;

- An unplanned ignition or explosion of gas or dust;

- An unplanned mine fire not extinguished within 30 minutes of discovery;

- An unplanned ignition or explosion of a blasting agent or an explosive;

- An unplanned roof fall at or above the anchorage zone in active workings where roof bolts are in use; or, an unplanned roof or rib fall in active workings that impairs ventilation or impedes passage;

- A coal or rock outburst that causes withdrawal of miners or which disrupts regular mining activity for more than one hour;

- An unstable condition at an impoundment, refuse pile, or culm bank which requires emergency action in order to prevent failure, or which causes individuals to evacuate an area; or, failure of an impoundment, refuse pile or culm bank;

- Damage to hoisting equipment in a shaft or slope which endangers an individual or which interferes with use of the equipment for more than thirty minutes; and

- An event at a mine which causes death or bodily injury to an individual not at the mine at the time the event occurs.

Additionally, the Mine Safety and Health Act authorizes the National Institute for Occupational Safety and Health (NIOSH), part of the Centers for Disease Control and Prevention under the U.S. Department of Health and Human Services to develop recommendations for mine health standards for the Mine Safety and Health Administration; administer a medical surveillance program for miners, including chest X-rays to detect pneumoconiosos (black lung disease) in coal miners; conduct on-site investigations in mines; and test and certify personal protective equipment and hazard-measurement instruments.

Statistical analyses performed by the U.S. Department of Labor's Mine Safety and Health Administration (MSHA) show that between 1990 and 2004, the industry cut the rate of injuries (a measure comparing the rate of incidents to overall number of employees or hours worked) by more than half and fatalities by two-thirds following three prior decades of steady improvement.

Machinery

Heavy machinery is needed in mining for exploration and development, to remove and stockpile overburden, to break and remove rocks of diverse hardness and toughness, and to process the ore as well as for reclamation. Bulldozers, drills, explosives and trucks are important for digging into the land, especially in surface mining.

Underground mining, like continuous mining, tends to be more technologically sophisticated because of the dangers and expense of subsurface tunneling.

Trams are used to transport miners, minerals and waste.

Mining machinery manufacturers include Atlas Copco, Joy Mining Machinery, Bucyrus International, Caterpillar, Komatsu, Volvo, Hitachi, Terex, Dresser Industries, Kawasaki, Eimco Elecon India Limited, and Liebherr.

Placer mining is a type of surface mining, usually for gold, tin, and other metals, and gemstones. Ore, typically unconsolidated gravels ( alluvium), is fed into machinery that may consist of a hopper, shaking screen or trommel which frees the minerals from the gravels. The target minerals are then concentrated using sluices or jigs.

Abandoned mines

The number of abandoned mines in the United States remains an unknown, ranging "from the National Park Service's tally of 2,500 on its lands, to the Mineral Policy Centre's assessment of 560,000 abandoned mines on public and privately owned lands." Many of these abandoned mines are associated with abandoned neighboring towns often referred to as ghost towns. Experts strongly warn against entering or exploring old or abandoned mines.

In the U.S., the estimation is that approximately 25% of the abandoned mine lands (AML) sites pose physical safety hazards. Old mines are often dangerous and can contain deadly gases. Since weather may have eroded the earth/rock surrounding it, the entrance to an old mine in particular can be very dangerous. Old mine workings, caves, etc. are commonly hazardous simply due to the lack of oxygen in the air (a condition in mines known as blackdamp). Blackdamp is a deadly killer which provides no warning to any individual or group of individuals entering such an environment.

Every year, dozens are injured or killed in recreational accidents on mine property. It is only fair to note, however, that the majority of the deaths are unrelated to mine exploration. Drownings in open quarries and ATV accidents on abandoned mine properties are the main cause of accidental death. The U.S. Department of Labor notes that since 1999, "more than 200 people have died in recreational accidents at surface and underground active and abandoned operations across the country." Due to these circumstances, MSHA ( Mine Safety and Health Administration) launched the "Stay Out – Stay Alive" campaign, which is a national public awareness campaign aimed at warning and educating children and adults about the dangers of exploring and playing on active and abandoned mine sites.

In the U.S., the Abandoned Mine Land Initiative, launched by the Western Governor's Association and the National Mining Association is also an effort focusing on reporting the number of high-priority AML sites. The initiative identifies, measures and reports on the progress of current reclamation cleanup programs on an annual basis. In the Americas region, the United Nations Environment Programme (UNEP) and the Chilean Copper Commission (COHILCO) co-hosted a workshop to address the problem of abandoned or "orphaned" mines. Including a representative from the UN, ten countries were represented from North, Central and South America with an eleventh participant being Japan.

Records

- The deepest mine in the world: Savuka Mine in the North West Province, South Africa at 3,774 meters

- East Rand Mine in Boksburg, South Africa briefly held the record at 3,585 meters

- The first mine declared the deepest in the world was TauTona in Carletonville, South Africa at 3,581 meters. Plans exist to extend TauTona to a depth of 3,902 meters by July 2008, which will make it the deepest again.

- The deepest open pit mine in the world: Bingham Canyon Mine in Bingham Canyon, Utah, USA at over 1,200 meters

- The largest and second deepest open pit copper mine in the world: Chuquicamata in Chuquicamata, Chile at 900 meters, 940.600 Tons of fine copper and 17.700 Tons of molybdenum

- The largest underground mine: El Teniente, in Rancagua, Chile, 2400 kilometers of underground drifts, 418.000 Tons of copper yearly

- The deepest mine in Europe: Pyhäsalmi Mine in Pyhäjärvi, Finland at 1,444 meters

- The second deepest mine in Europe: Boulby Mine England at 1,400 meters (shaft depth 1,100 meters)

- Sweden's largest underground mine: Kirunavaara mine in Kiruna, Sweden, 450 kilometers of roads, 40 million tonnes of ore produced yearly, depth 1270 meters.

- The deepest borehole in the world: Kola Superdeep Borehole at 12,262 meters. This, however, is not a matter of mining but rather related to scientific drilling.