Coal

2008/9 Schools Wikipedia Selection. Related subjects: Environment; Mineralogy

Coal is a fossil fuel formed in ecosystems where plant remains were preserved by water and mud from oxidization and biodegradation, thus sequestering atmospheric carbon. Coal is a readily combustible black or brownish-black rock. It is a sedimentary rock, but the harder forms, such as anthracite coal, can be regarded as metamorphic rocks because of later exposure to elevated temperature and pressure. It is composed primarily of carbon and hydrogen along with small quantities of other elements, notably sulfur. It is the largest source of fuel for generation of electricity world-wide, as well as the largest world-wide source of carbon dioxide emissions, which according to the IPCC, contribute to climate change and global warming. In terms of carbon dioxide emissions, coal is slightly ahead of petroleum and about double that of natural gas. Coal is extracted from the ground by coal mining, either underground mining or open pit mining ( surface mining).

Types of coal

As geological processes apply pressure to dead biotic matter over time, under suitable conditions it is transformed successively into

- Peat, considered to be a precursor of coal. It has industrial importance as a fuel in some countries, for example, Ireland and Finland.

- Lignite, also referred to as brown coal, is the lowest rank of coal and used almost exclusively as fuel for electric power generation. Jet is a compact form of lignite that is sometimes polished and has been used as an ornamental stone since the Iron Age.

- Sub-bituminous coal, whose properties range from those of lignite to those of bituminous coal and are used primarily as fuel for steam-electric power generation. Additionally, it is an important source of light aromatic hydrocarbons for the chemical synthesis industry.

- Bituminous coal, a dense mineral, black but sometimes dark brown, often with well-defined bands of bright and dull material, used primarily as fuel in steam-electric power generation, with substantial quantities also used for heat and power applications in manufacturing and to make coke.

- Anthracite, the highest rank; a harder, glossy, black coal used primarily for residential and commercial space heating. It may be divided further in to metamorphically altered bituminous coal and petrified oil, as from the deposits in Pennsylvania.

- Graphite, technically the highest rank, but difficult to ignite and is not so commonly used as fuel: it is mostly used in pencils and, when powdered, as a lubricant.

The classification of coal is generally based on the content of volatiles. However, the exact classification varies between countries. According to the German classification, coal is classified as follows:

| Name | Volatiles % | C Carbon % | H Hydrogen % | O Oxygen % | S Sulfur % | Heat content kJ/kg |

|---|---|---|---|---|---|---|

| Braunkohle (Lignite) | 45-65 | 60-75 | 6.0-5.8 | 34-17 | 0.5-3 | <28470 |

| Flammkohle (Flame coal) | 40-45 | 75-82 | 6.0-5.8 | >9.8 | ~1 | <32870 |

| Gasflammkohle (Gas flame coal) | 35-40 | 82-85 | 5.8-5.6 | 9.8-7.3 | ~1 | <33910 |

| Gaskohle (Gas coal) | 28-35 | 85-87.5 | 5.6-5.0 | 7.3-4.5 | ~1 | <34960 |

| Fettkohle (Fat coal) | 19-28 | 87.5-89.5 | 5.0-4.5 | 4.5-3.2 | ~1 | <35380 |

| Esskohle (Forge coal) | 14-19 | 89.5-90.5 | 4.5-4.0 | 3.2-2.8 | ~1 | <35380 |

| Magerkohle (Non baking coal) | 10-14 | 90.5-91.5 | 4.0-3.75 | 2.8-3.5 | ~1 | 35380 |

| Anthrazit (Anthracite) | 7-12 | >91.5 | <3.75 | <2.5 | ~1 | <35300 |

The middle six grades in the table represent a progressive transition from the English-language sub-bituminous to bituminous coal, while the last class is an approximate equivalent to anthracite, but more inclusive (the U.S. anthracite has < 8% volatiles).

Early use

China Coal Information Institute reports the Chinese mined coalstone for fuel 10,000 years ago at the time of the New Stone Age, or Neolithic Era. "People in Shanxi, now the largest coal production base, have been burning coal as fuel since then." Outcrop coal was used in Britain during the Bronze Age (2000-3000 years BC), where it has been detected as forming part of the composition of funeral pyres. It was also commonly used in the early period of the Roman occupation: Evidence of trade in coal (dated to about AD 200) has been found at the inland port of Heronbridge, near Chester, and in the Fenlands of East Anglia, where coal from the Midlands was transported via the Car Dyke for use in drying grain. Coal cinders have been found in the hearths of villas and military forts, particularly in Northumberland, dated to around AD 400. In the west of England contemporary writers described the wonder of a permanent brazier of coal on the altar of Minerva at Aquae Sulis (modern day Bath) although in fact easily-accessible surface coal from what is now the Somerset coalfield was in common use in quite lowly dwellings locally.

However, there is no evidence that the product was of great importance in Britain before the High Middle Ages, after about AD 1000. Mineral coal came to be referred to as "seacoal," probably because it came to many places in eastern England, including London, by sea. This is accepted as the more likely explanation for the name than that it was found on beaches, having fallen from the exposed coal seams above or washed out of underwater coal seam outcrops. These easily accessible sources had largely become exhausted (or could not meet the growing demand) by the 13th century, when underground mining from shafts or adits was developed. In London there is still a Seacoal Lane (off the north side of Ludgate Hill) where the coal merchants used to conduct their business. An alternative name was "pitcoal," because it came from mines. It was, however, the development of the Industrial Revolution that led to the large-scale use of coal, as the steam engine took over from the water wheel.

Uses today

Coal as fuel

Coal is primarily used as a solid fuel to produce electricity and heat through combustion. World coal consumption is about 6.2 billion tons annually, of which about 75% is used for the production of electricity. China produced 2.38 billion tons in 2006 and India produced about 447.3 million tons in 2006. 68.7% of China's electricity comes from coal. The USA consumes about 1.053 billion tons of coal each year, using 90% of it for generation of electricity. The world in total produced 6.19 billion tons of coal in 2006.

When coal is used for electricity generation, it is usually pulverized and then burned in a furnace with a boiler. The furnace heat converts boiler water to steam, which is then used to spin turbines which turn generators and create electricity. The thermodynamic efficiency of this process has been improved over time. "Standard" steam turbines have topped out with some of the most advanced reaching about 35% thermodynamic efficiency for the entire process, which means 65% of the coal energy is waste heat released into the surrounding environment. Old coal power plants, especially "grandfathered" plants, are significantly less efficient and produce higher levels of waste heat.

The emergence of the supercritical turbine concept envisions running a boiler at extremely high temperatures and pressures with projected efficiencies of 46%, with further theorized increases in temperature and pressure perhaps resulting in even higher efficiencies.

Other efficient ways to use coal are combined cycle power plants, combined heat and power cogeneration, and an MHD topping cycle.

Approximately 40% of the world electricity production uses coal. The total known deposits recoverable by current technologies, including highly polluting, low energy content types of coal (i.e., lignite, bituminous), might be sufficient for 300 years' use at current consumption levels, although maximal production could be reached within decades (see World Coal Reserves, below).

A more energy-efficient way of using coal for electricity production would be via solid-oxide fuel cells or molten-carbonate fuel cells (or any oxygen ion transport based fuel cells that do not discriminate between fuels, as long as they consume oxygen), which would be able to get 60%–85% combined efficiency (direct electricity + waste heat steam turbine). Currently these fuel cell technologies can only process gaseous fuels, and they are also sensitive to sulfur poisoning, issues which would first have to be worked out before large scale commercial success is possible with coal. As far as gaseous fuels go, one idea is pulverized coal in a gas carrier, such as nitrogen. Another option is coal gasification with water, which may lower fuel cell voltage by introducing oxygen to the fuel side of the electrolyte, but may also greatly simplify carbon sequestration.

Coking and use of coke

Coke is a solid carbonaceous residue derived from low-ash, low-sulfur bituminous coal from which the volatile constituents are driven off by baking in an oven without oxygen at temperatures as high as 1,000 °C (1,832 °F) so that the fixed carbon and residual ash are fused together. Metallurgic coke is used as a fuel and as a reducing agent in smelting iron ore in a blast furnace. Coke from coal is grey, hard, and porous and has a heating value of 24.8 million Btu/ton (29.6 MJ/kg). Some cokemaking processes produce valuable by-products that include coal tar, ammonia, light oils, and " coal gas".

Petroleum coke is the solid residue obtained in oil refining, which resembles coke but contains too many impurities to be useful in metallurgical applications.

Gasification

High prices of oil and natural gas are leading to increased interest in "BTU Conversion" technologies such as gasification, methanation and liquefaction.

Coal gasification breaks down the coal into smaller molecular weight molecules, usually by subjecting it to high temperature and pressure, using steam and measured amounts of oxygen. This leads to the production of syngas, a mixture mainly consisting of carbon monoxide (CO) and hydrogen (H2).

In the past, coal was converted to make coal gas, which was piped to customers to burn for illumination, heating, and cooking. At present, the safer natural gas is used instead. South Africa still uses gasification of coal for much of its petrochemical needs.

The Synthetic Fuels Corporation was a U.S. government-funded corporation established in 1980 to create a market for alternatives to imported fossil fuels (such as coal gasification). The corporation was discontinued in 1985.

Gasification is also a possibility for future energy use, as the produced syngas can be cleaned-up relatively easily leading to cleaner burning than burning coal directly (the conventional way). The cleanliness of the cleaned-up syngas is comparable to natural gas enabling to burn it in a more efficient gas turbine rather than in a boiler used to drive a steam turbine. Syngas produced by gasification can be CO-shifted meaning that the combustible CO in the syngas is transferred into carbon dioxide (CO2) using water as a reactant. The CO-shift reaction also produces an amount of combustible hydrogen (H2) equal to the amount of CO converted into CO2. The CO2 concentrations (or rather CO2 partial pressures) obtained by using coal gasification followed by a CO-shift reaction are much higher than in case of direct combustion of coal in air (which is mostly nitrogen). These higher concentrations of carbon dioxide make carbon capture and storage much more economical than it otherwise would be.

Liquefaction - Coal-To-Liquids (CTL)

Coals can also be converted into liquid fuels like gasoline or diesel by several different processes. The Fischer-Tropsch process of indirect synthesis of liquid hydrocarbons was used in Nazi Germany for many years and is today used by Sasol in South Africa. Coal would be gasified to make syngas (a balanced purified mixture of CO and H2 gas) and the syngas condensed using Fischer-Tropsch catalysts to make light hydrocarbons which are further processed into gasoline and diesel. Syngas can also be converted to methanol, which can be used as a fuel, fuel additive, or further processed into gasoline via the Mobil M-gas process.

A direct liquefaction process Bergius process (liquefaction by hydrogenation) is also available but has not been used outside Germany, where such processes were operated both during World War I and World War II. SASOL in South Africa has experimented with direct hydrogenation. Several other direct liquefaction processes have been developed, among these being the SRC-I and SRC-II (Solvent Refined Coal) processes developed by Gulf Oil and implemented as pilot plants in the United States in the 1960s and 1970s.

Another direct hydrogenation process was explored by the NUS Corporation in 1976 and patented by Wilburn C. Schroeder. The process involved dried, pulverized coal mixed with roughly 1wt% molybdenum catalysts. Hydrogenation occurred by use of high temperature and pressure synthesis gas produced in a separate gasifier. The process ultimately yielded a synthetic crude product, Naphtha, a limited amount of C3/C4 gas, light-medium weight liquids (C5-C10) suitable for use as fuels, small amounts of NH3 and significant amounts of CO2.

Yet another process to manufacture liquid hydrocarbons from coal is low temperature carbonization (LTC). Coal is coked at temperatures between 450 and 700°C compared to 800 to 1000°C for metallurgical coke. These temperatures optimize the production of coal tars richer in lighter hydrocarbons than normal coal tar. The coal tar is then further processed into fuels. The Karrick process was developed by Lewis C. Karrick, an oil shale technologist at the U.S. Bureau of Mines in the 1920s.

All of these liquid fuel production methods release carbon dioxide (CO2) in the conversion process, far more than is released in the extraction and refinement of liquid fuel production from petroleum. If these methods were adopted to replace declining petroleum supplies, carbon dioxide emissions would be greatly increased on a global scale. For future liquefaction projects, Carbon dioxide sequestration is proposed to avoid releasing it into the atmosphere, though no pilot projects have confirmed the feasibility of this approach on a wide scale. As CO2 is one of the process streams, sequestration is easier than from flue gases produced in combustion of coal with air, where CO2 is diluted by nitrogen and other gases. Sequestration will, however, add to the cost.

The reaction of coal and water using high temperature heat from a nuclear reactor offers promise of liquid transport fuels that could prove carbon-neutral compared to petroleum use. The development of a reliable nuclear reactor that could provide 900 to 1000 deg C process heat, such as the pebble bed reactor, would be necessary.

Coal liquefaction is one of the backstop technologies that could potentially limit escalation of oil prices and mitigate the effects of transportation energy shortage that some authors have suggested could occur under peak oil. This is contingent on liquefaction production capacity becoming large enough to satiate the very large and growing demand for petroleum. Estimates of the cost of producing liquid fuels from coal suggest that domestic U.S. production of fuel from coal becomes cost-competitive with oil priced at around 35 USD per barrel, (break-even cost). The current price of oil, as of July 11, 2008, is 145 USD per barrel. This makes coal a viable financial alternative to oil for the time being, although current production is small.

Among commercially mature technologies, advantage for indirect coal liquefaction over direct coal liquefaction are reported by Williams and Larson (2003). Estimates are reported for sites in China where break-even cost for coal liquefaction may be in the range between 25 to 35 USD/barrel of oil.'

Intensive research and project developments have been implemented from 2001. The World CTL Award is granted to personalities having brought eminent contribution to the understanding and development of Coal liquefaction. The 2009 presentation ceremony will take place in Washington DC (USA) at the World CTL 2009 Conference (25-27 March, 2009).

Coal as a traded commodity

The price of coal has gone up from around $30 per short ton in 2000 to around $123.50 per short ton as of June 25th, 2008.

In North America, a Central Appalachian coal futures contract is currently traded on the New York Mercantile Exchange (trading symbol QL). The trading unit is 1,550 short tons per contract, and is quoted in U.S. dollars and cents per ton. Since coal is the principal fuel for generating electricity in the United States, the futures contract provides coal producers and the electric power industry an important tool for hedging and risk management.

In addition to the NYMEX contract, the IntercontinentalExchange (ICE) has European (Rotterdam) and South African (Richards Bay) coal futures available for trading. The trading unit for these contracts is 5,000 tons, and are also quoted in U.S. dollars and cents per ton.

Cultural usage

Coal is the official state mineral of Kentucky and the official state rock of Utah. Both U.S. states have a historic link to coal mining.

Some cultures uphold that children who misbehave will receive coal from Santa Claus for Christmas in their stockings instead of presents.

It is also customary and lucky in Scotland to give coal as a gift on New Year's Day. It happens as part of First-Footing and represents warmth for the year to come.

Environmental effects

There are a number of adverse environmental effects of coal mining and burning.

These effects include:

- release of carbon dioxide and methane, both of which are greenhouse gases, which are causing climate change and global warming according to the IPCC. Coal is the largest contributor to the human-made increase of CO2 in the air.

- waste products including uranium, thorium, and other heavy metals

- acid rain

- interference with groundwater and water table levels

- impact of water use on flows of rivers and consequential impact on other land-uses

- dust nuisance

- subsidence above tunnels, sometimes damaging infrastructure

- rendering land unfit for other uses.

- coal-fired power plants without effective fly ash capture are one of the largest sources of human-caused background radiation exposure.

Energy density

The energy density of coal, i.e. its heating value, is roughly 24 megajoules per kilogram.

The energy density of coal can also be expressed in kilowatt-hours for some unit of mass, the units that electricity is most commonly sold in, to estimate how much coal is required to power electrical appliances. The energy density of coal is 6.67 kW·h/kg and the typical thermodynamic efficiency of coal power plants is about 30%. Of the 6.67 kW·h of energy per kilogram of coal, about 30% of that can successfully be turned into electricity—the rest is waste heat. Coal power plants obtain approximately 2.0 kW·h per kg of burned coal.

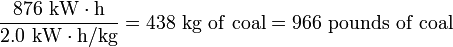

As an example, running one 100 watt computer for one year requires 876 kW·h (100 W × 24 h/day × 365 {days in a year} = 876000 W·h = 876 kW·h). Converting this power usage into physical coal consumption:

It takes 438 kg (966 pounds) of coal to power a computer for one full year. One should also take into account transmission and distribution losses caused by resistance and heating in the power lines, which is in the order of 5–10%, depending on distance from the power station and other factors.

Relative carbon cost

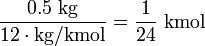

Because coal is at least 50% carbon (by mass), then 1 kg of coal contains at least 0.5 kg of carbon, which is

where 1 mol is equal to NA (Avogadro Number) particles.

where 1 mol is equal to NA (Avogadro Number) particles.

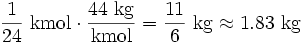

This combines with oxygen in the atmosphere during combustion, producing carbon dioxide, with an atomic weight of (12 + 16 × 2 = mass(CO2) = 44 kg/kmol), so 1⁄24 kmol of CO2 is produced from the 1⁄24 kmol present in every kilogram of coal, which once trapped in CO2 weighs approximately

.

.

This can be used to put a carbon-cost of energy on the use of coal power. Since the useful energy output of coal is about 30% of the 6.67 kW·h/kg(coal), we can say about 2 kW·h/kg(coal) of energy is produced. Since 1 kg coal roughly translates as 1.83 kg of CO2, we can say that using electricity from coal produces CO2 at a rate of about 0.915 kg/(kW·h), or about 0.254 kg/MJ.

This estimate compares favourably with the U.S. Energy Information Agency's 1999 report on CO2 emissions for energy generation, which quotes a specific emission rate of 950 g CO2/(kW·h). By comparison, generation from oil in the U.S. was 890 g CO2/(kW·h), while natural gas was 600 g CO2/(kW·h). Estimates for specific emission from nuclear power, hydro, and wind energy vary, but are about 100 times lower. See environmental effects of nuclear power for estimates.

Coal fires

There are hundreds of coal fires burning around the world. Those burning underground can be difficult to locate and many cannot be extinguished. Fires can cause the ground above to subside, their combustion gases are dangerous to life, and breaking out to the surface can initiate surface wildfires. Coal seams can be set on fire by spontaneous combustion or contact with a mine fire or surface fire. A grass fire in a coal area can set dozens of coal seams on fire. Coal fires in China burn 109 million tons of coal a year, emitting 360 million metric tons of CO2. This contradicts the ratio of 1:1.83 given earlier, but it amounts to 2-3% of the annual worldwide production of CO2 from fossil fuels, or as much as emitted from all of the cars and light trucks in the United States. In Centralia, Pennsylvania (a borough located in the Coal Region of the United States) an exposed vein of coal ignited in 1962 due to a trash fire in the borough landfill, located in an abandoned anthracite strip mine pit. Attempts to extinguish the fire were unsuccessful, and it continues to burn underground to this day. The Australian Burning Mountain was originally believed to be a volcano, but the smoke and ash comes from a coal fire which may have been burning for over 5,500 years.

At Kuh i Malik in Yagnob Valley, Tajikistan, coal deposits have been burning for thousands of years, creating vast underground labyrinths full of unique minerals, some of them very beautiful. Local people once used this method to mine ammoniac. This place has been well-known since the time of Herodotus, but European geographers mis-interpreted the Ancient Greek descriptions as the evidence of active volcanism in Turkestan (up to the 19th century, when Russian army invaded the area).

The reddish siltstone rock that caps many ridges and buttes in the Powder River Basin ( Wyoming), and in western North Dakota is called porcelanite, which also may resemble the coal burning waste "clinker" or volcanic " scoria". Clinker is rock that has been fused by the natural burning of coal. In the Powder River Basin approximately 27 to 54 billion tons of coal burned within the past three million years. Wild coal fires in the area were reported by the Lewis and Clark Expedition as well as explorers and settlers in the area.

Production trends

In 2006, China was the top producer of coal with 38% share followed by the USA and India, reports the British Geological Survey.

World coal reserves

At the end of 2006 the recoverable coal reserves amounted around 800 or 900 gigatons. The United States Energy Information Administration gives world reserves as 998 billion short tons (equal to 905 gigatons), approximately half of it being hard coal. At the current production rate, this would last 164 years. At the current global total energy consumption of 15 terawatt, there is enough coal to provide the entire planet with all of its energy for 57 years.

The 998 billion tons of recoverable coal reserves estimated by the Energy Information Administration are equal to about 4,417 BBOE (billion barrels of oil equivalent). The amount of coal burned during 2001 was calculated as 2.337 GTOE (gigatonnes of oil equivalent), which is about 46 million barrels of oil equivalent per day. Were consumption to continue at that rate those reserves would last about 263 years. As a comparison, natural gas provided 51 million barrels (oil equivalent), and oil 76 million barrels, per day during 2001.

British Petroleum, in its annual report 2007, estimated at 2006 end, there were 909,064 million tons of proven coal reserves worldwide, or 147 years reserves to production ratio. This figure only includes reserves classified as "proven"; exploration drilling programs by mining companies, particularly in under-explored areas, are continually providing new reserves. In many cases, companies are aware of coal deposits that have not been sufficiently drilled to qualify as "proven". However, some nations haven't updated their information and assume reserves remain at the same levels even with withdrawals.

Of the three fossil fuels coal has the most widely distributed reserves; coal is mined in over 100 countries, and on all continents except Antarctica. The largest reserves are found in the USA, Russia, Australia, China, India and South Africa.

Note the table below.

| Country | Bituminous & anthracite | SubBituminous & lignite | TOTAL | Share |

|---|---|---|---|---|

| 111,338 | 135,305 | 246,643 | 27.1 | |

| 49,088 | 107,922 | 157,010 | 17.3 | |

| 62,200 | 52,300 | 114,500 | 12.6 | |

| 90,085 | 2,360 | 92,445 | 10.2 | |

| 38,600 | 39,900 | 78,500 | 8.6 | |

| 48,750 | 0 | 48,750 | 5.4 | |

| 16,274 | 17,879 | 34,153 | 3.8 | |

| 28,151 | 3,128 | 31,279 | 3.4 | |

| 14,000 | 0 | 14,000 | 1.5 | |

| 0 | 10,113 | 10,113 | 1.1 | |

| 183 | 6,556 | 6,739 | 0.7 | |

| 6,230 | 381 | 6,611 | 0.7 | |

| 3,471 | 3,107 | 6,578 | 0.7 | |

| 2,094 | 3,458 | 5,552 | 0.6 | |

| 740 | 4,228 | 4,968 | 0.5 | |

| 278 | 3,908 | 4,186 | 0.5 | |

| 0 | 3,900 | 3,900 | 0.4 | |

| 198 | 3,159 | 3,357 | 0.4 | |

| 0 | 3,050 | 3,050 | 0.3 | |

| 4 | 2,183 | 2,187 | 0.2 | |

| 0 | 1,354 | 1,354 | 0.1 | |

| 300 | 300 | 600 | 0.1 | |

| 33 | 538 | 571 | 0.1 | |

| 200 | 330 | 530 | 0.1 | |

| 502 | 0 | 502 | 0.1 | |

| 22 | 472 | 494 | 0.1 | |

| 479 | 0 | 479 | 0.1 | |

| TOTAL | 478,771 | 430,293 | 909,064 | 100.0 |

Major coal producers

| Country | 2003 | 2004 | 2005 | 2006 |

|---|---|---|---|---|

| PR China | 1722.0 | 1992.3 | 2204.7 | 2380.0 |

| United States | 972.3 | 1008.9 | 1026.5 | 1053.6 |

| India | 375.4 | 407.7 | 428.4 | 447.3 |

| Australia | 351.5 | 366.1 | 378.8 | 373.8 |

| Russian Federation | 276.7 | 281.7 | 298.5 | 309.2 |

| South Africa | 237.9 | 243.4 | 244.4 | 256.9 |

| Germany | 204.9 | 207.8 | 202.8 | 197.2 |

| Indonesia | 114.3 | 132.4 | 146.9 | 195.0 |

| Poland | 163.8 | 162.4 | 159.5 | 156.1 |

| Total World | 5187.6 | 5585.3 | 5886.7 | 6195.1 |

Major coal exporters

| Country | 2003 | 2004 | 2005 |

|---|---|---|---|

| Australia | 238.1 | 247.6 | 257.6 |

| United States | 43.0 | 48.0 | 49.9 |

| South Africa | 78.7 | 74.9 | 77.5 |

| CIS (Former Soviet Union) | 41.0 | 55.7 | 62.3 |

| Poland | 16.4 | 16.3 | 16.4 |

| Canada | 27.7 | 28.8 | 31.0 |

| China | 103.4 | 95.5 | 79.0 |

| South America | 57.8 | 65.9 | 68.8 |

| Indonesia | 107.8 | 131.4 | 147.6 |

| Vietnam | N/A | 10.3 | 14.1 |

| Total | 713.9 | 764.0 | 804.2 |